Diamond tooling is the contractor’s best friend

The single, most important aspect of the concrete polishing industry is “the diamond tool.” KutRite Manufacturing has been dealing with abrasive tooling and general surface preparation for many years. With over 60 years of combined experience in sales and real world experience, KutRite products are the best choice for the busy contractor looking for quality and longevity.

KutRite has over a decade’s worth of experience working closely with diamond manufacturers. We pride ourselves in the amount of time and money that we invest in premium KutRite diamond tools. We take the same care in research and development during the manufacturing of our carbide and steel cutters.

The diamond tool is the reason concrete can be polished. It has the ability to abrade away the hard surface of the concrete and mechanically process the concrete into a sustainable, pleasing-to-the-eye wearable surface. The tools make this happen with the help of a quality manufactured surface grinder and a skilled, patient operator.

KutRite works closely with our No. 1 partner in the development of diamond tooling. The commitment that our partners have shown is second to none. We develop the tools using our equipment, giving KutRite and its partners a deep understanding of the machinery. Each machine in the industry has different characteristics. That’s why we take the time to develop the machine and tooling “as one.” This gives our customers a “custom fit” with every product that they purchase. We do not just buy and sell any diamond tool and hope it works. Most products from overseas do not have the strict quality control exhibited by American-made products. KutRite Manufacturing takes great pride in that fact.

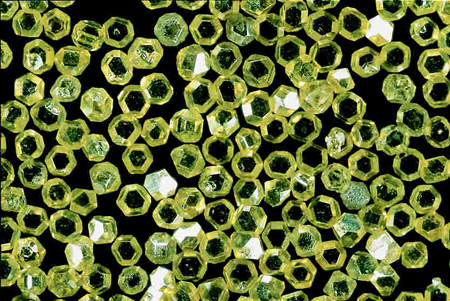

A quality metal bond diamond tool will have even distribution all the way through the segment down to the base plate. It will have great wear capability and the latest technology in synthetic and natural diamond raw material. The raw diamonds will be able to sustain the most aggressive debris created by the grinding of the concrete and the removal of highly abrasive coatings. A good diamond will wear naturally and consistently, giving the operator the confidence going into each job.

Transition tools should be of the same quality. These tools are the steppingstone between the initial grind and the finish polish. A good transition tool will give the floor a tighter scratch, eliminating the deeper scratches left by the metal bond.

Resin and polishing pads are the softest pads used for the last steps of the mechanical polishing process. These pads have a greater raw diamond count and are used to finish the process. This type of diamond should have even distribution as well as high diamond count and should not have any dead areas.

When it is all said and done, the contractor will experience different types of concrete on every job. The tools are the extension of his or her knowledge. It is important that the diamond tooling be supplied and supported by an experienced, knowledgeable supplier.

KutRite Manufacturing has the experience and knowledge to diagnose and treat all the symptoms presented in any removal and polishing application.